The Packaging Valley, Emilia Romagna

The area between Bologna and Reggio Emilia encloses a significant number of packaging machinery factories that together give shape to the manufacturing district with the highest density in Europe of companies of this industry.

This so-called “Packaging Valley” includes about 200 companies that contribute to assuring the “made in Italy” top quality all over the world. Together they have a revenue of over 2,000 billion and an exportation rate that exceeds 80% as more than 50% of the machinery for packaging sold globally is produced here.

The most famous companies are based in this area: they produce packaging for food, pharmaceuticals and cosmetics. But there are also several smaller factories operating in market niches, such as the tobacco industry.

New sustainability challenges

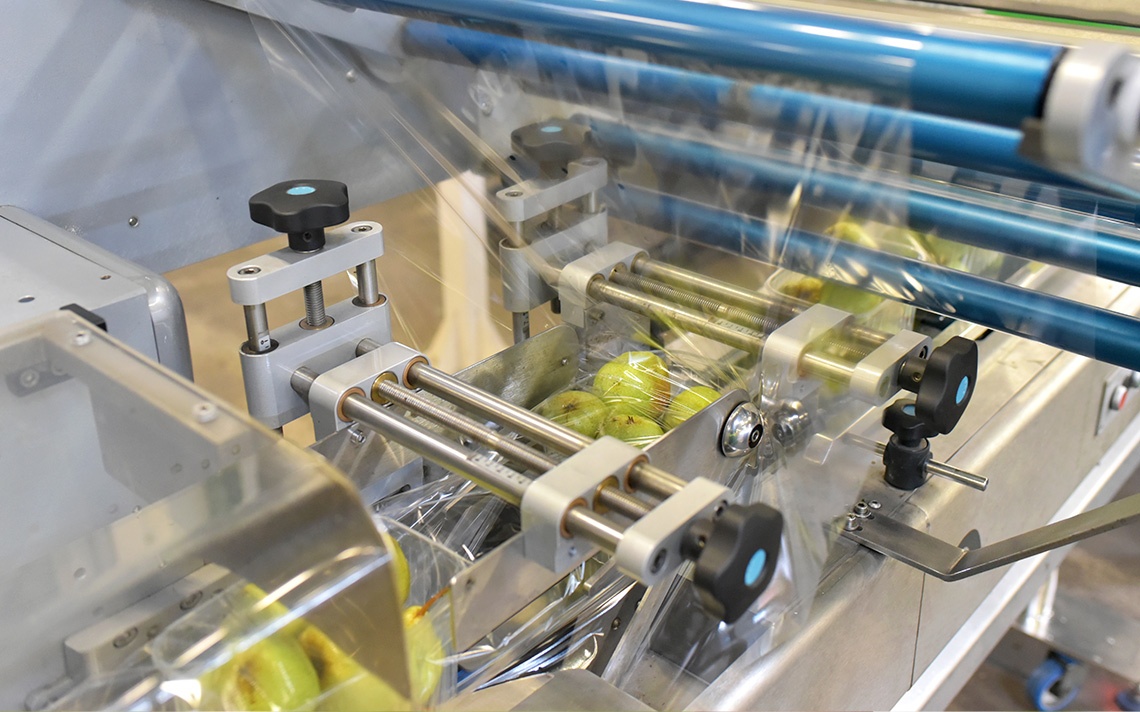

Plastic, thanks to its properties, which are ideal for product preservation and transport, has always played a key role in the packages fabricated in this flourishing industry.

However, in the last few years, the focus on environmental impact has become a bigger and bigger issue in this market as well, with better awareness from both companies and consumers.

According to a survey conducted by Nielsen, in 2019 more than 40% of food and body care product buyers were already basing their choices on whether the packages were sustainable. As the popularity of packaged products - connected to the pandemic and the fast spread of delivery services - increased, the issues about disposal and recycle entered the discourse on all levels.

For example, with the European Circular Economy Strategy for plastics, the European Union has set the goal to assure that, by 2030, all plastic packaging must be 100% recyclable.

Italy is a role model in the practices linked to circular economy in several areas, but the war on plastics has caused distress in the packaging industry. It’s especially the plastic tax planned for 2023 that most worries about the future of the Packaging Valley.

Green packages

Finding more sustainable options that allow the same performances as plastic at a reasonable price is not easy for these companies.

To take a stand on sustainability, many companies have taken action on their energy production system by updating the production chain in order to reduce CO₂ emissions.

Some companies like Tetra Pak have shifted to a production of mainly paper and cardboard packages, a trend seemingly largely appreciated by consumers and encouraged by the easy recyclability.

On the other hand, some other packaging makers are trying to defend the use of plastics by spreading awareness about the smaller amount of energy and fuel this material needs for production and transport compared to others, and the possibility of recycle and energy recovery its use allows.

According to Augusto Bianchini, the professor at the University of Bologna who has curated the “Ricircola” project: «The issue is not plastic, but its waste that must be reduced and managed».

This industry in its entirety is moving towards a context of a more total plastic recycle.

From this point of view, one of the most viable alternatives is the recycle of polyethylene terephthalate (PET), one of the plastic materials most used in packaging.

Even the European Union is encouraging the spread of r-PET, the material derived from post-consumer polyethylene that, in addition to fueling circular processes, allows the packaging of food in compliance with the health and safety guidelines written in consumer protection laws.

Which material will be the perfect solution for more ecofriendly packages in the long run? That is yet to be decided, but the necessity of taking sustainability into account is absolutely evident for the companies of this industry in particular: only by reducing its waste the district will be able to keep a high production level and prosper.